Products

Specializing In The Development And Manufacture Of Rubber Additives

Antiscorching agent CTP(80)

Classification:

Features

Introduce

HENAN TANGYIN YONGXIN AUXILIARY AGENT FACTORY ANTISCORCHING AGENT CTP(PVI)—80( white granulate containing 20% of wax)

CAS NO.:17796-82-6

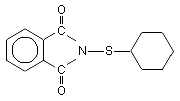

Chemical Name: N-(cyclohexylthio)Phthalimide

Granular CTP with non-toxic wax can prevent the irritation, diminishes the losses during the operation, and assure the excellent dispersion.

Empirical Formula:C14H15O2SN

Molecular Weight:261.3

Chemical Structure:

Physical Form: White or off white granule

Technical Parameters:

| Active substance(CTP) | ≥77% |

| Wax Content | 17-21% |

| Weight Loss | ≤0.50 |

| Ash Content | ≤0.1 |

| Toluene Insolubles | ≤3.0 |

| Melting Point | 88-94℃ |

Properties: Soluble in Benzene, Toluene, Acetone, Ethyl Acetate, Insoluble in Ethanol and gasoline, Reacts with water.

Application:

It is a high effective pre-vulcanization inhibitor. It’s applied in NR、SBR、BR、IIR、CR、EPM、EPDM、NBR with cure system consisting of sulfur and Thiazole but mainly Sulfenamide Accelerator. Even a small addition of this products to rubber compounds (0.1-0.5 phr.) increase their processing safety and that enables to speed up some of the technological operations during the preparation of rubber goods. Its use saves raw materials and power. In the vulcanization, wax play a role of vulcanization activator. Activity is linear and higher than most retarders; It can improve the storage stability of rubbers, avoid natural vulcanization during storage; It can recenerate the rubbers which was heated before or which was in the danger of burning with the result that it can not be processed furthermore; It’s free from the side effect of foaming and polluting.

use:

1, can prevent occur early in the process of processing rubber vulcanization, improve the safety of processing, and performance of vulcanization rate and vulcanization glue material had little influence.

2, because can effectively prevent the charred, calender, extruder to be high temperature and high speed, and can effectively use powerful vulcanizing agent, improve the production ability of vulcanizing machine, total production capacity increase of the factory.

3, can greatly improve the storage stability of rubber, prevent natural sulfide in during storage.

4, can and accelerator NS, M, DM, CBS and effective or half vulcanization system and effectively, improve the sizing performance.

5, due to the season and improper operation and cooperate and have suffered high fever rubber or with charred danger cannot further processing of rubber, this product has the effect of regenerative restoration.

6, no foam, adverse side effects such as pollution.

7, mainly used in natural rubber, synthetic rubber, especially with the time when the class promoter and sulfonamide, form a good vulcanization system.

Packaging and Storage:

The products should be stored and transported on pallets in dry and covered places and vehicles. Storage life in undamaged original packaging is 2 year under the observation of storage conditions.

Tel

Mobile website